Key Takeaway:

- Infrared curing systems provide a faster and more efficient method of curing powder coat, making it an excellent choice for those with limited space and production speeds.

- Compared to traditional ovens, infrared curing systems offer lower operation, capital, and upkeep costs, with a highly efficient heat and energy distribution system.

- While infrared curing systems have numerous benefits, there are some cons to consider, such as their difficulty with temperature-sensitive substrates or heavier coatings. However, these are easily mitigated by proper positioning of the lights and using the correct heating settings.

Stuck tryin’ to sort out your powder coat project, but don’t have an oven? Not a problem! You can still get pro-looking results, with these DIY-tricks. Follow this guide and make your next paint job a breeze. Learn how to cure powder coating today!

Introduction

To cure powder coat without an oven, there are several alternatives to consider. Infrared curing systems offer a targeted heat approach, while radiation and hot elements can provide even finishes. Production throughput may increase with reduced operation costs and capital costs. Despite the various pros and cons, zoned heating and quick heat up times make infrared systems an attractive option. Safety tips include considering air transparency and avoiding solvent-based coatings and temperature-sensitive substrates.

Although innovative, it is important to evaluate the efficiency of infrared systems compared to conventional ovens, microwaves, and ultraviolet radiation. Environmental factors such as CO2 emissions and power consumption should also be considered.

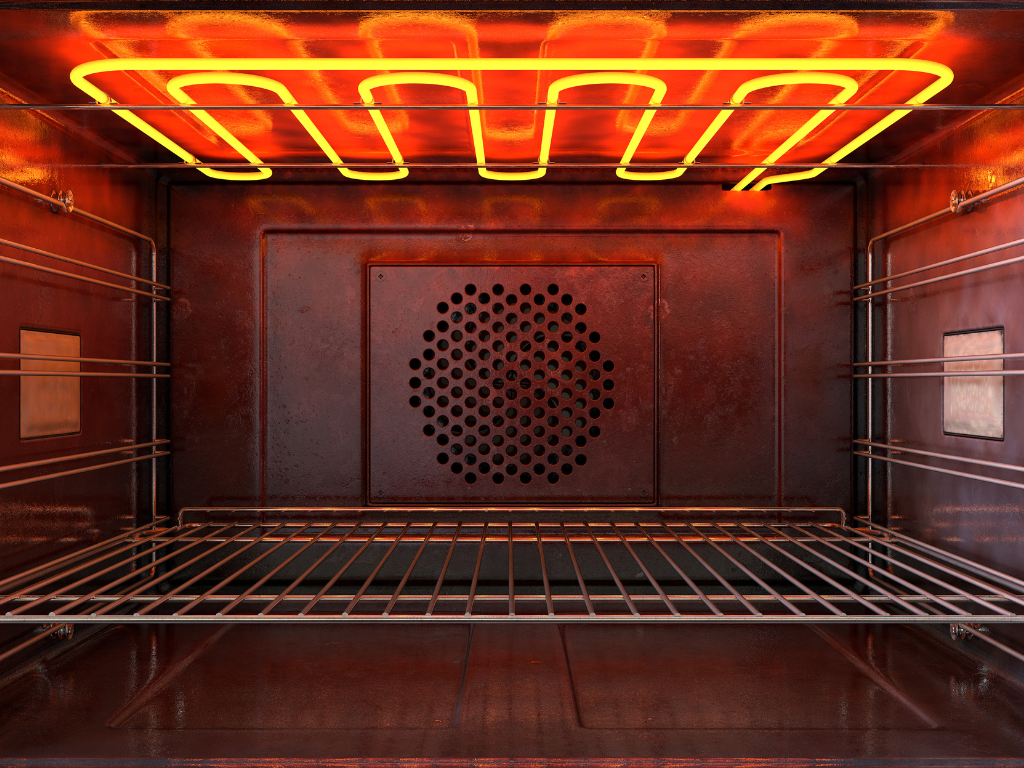

What is an Infrared Curing System?

An Infrared Curing System is a type of curing system that uses infrared radiation to cure materials such as powder coating, without the need for an oven. It saves floor space, quick to heat up and cool down, efficient in energy, and easy to use. Infrared curing systems are game changers in the industry, as they provide innovative cost-cutting solutions resulting in quality output. They support environmentally friendly practices by using recycled and standard materials for manufacturing replacement parts.

Using an Infrared Curing System can help in situations where an oven approach is not possible due to limited space or upkeep costs. They are particularly useful when handling heavy coatings that require quick and efficient curing. Additionally, they provide a safer alternative to curing with an oven, particularly for those who might not feel comfortable working with such high heat levels.

Consider investing in an Infrared Curing System to improve your operations and lower your costs today. Without one, you risk missing out on the streamlined efficiency and quality output that this system can provide.

Lamps for radiated heat transfer

Infrared curing systems use lamps for radiated heat transfer, which are energy-efficient and quick to cool down. They have saved floor space and material costs by using recycled materials while also reducing emissions into the environment.

The following table shows the advantages of different types of lamps used in infrared curing systems:

| Type of Lamp | Advantages |

|---|---|

| Tungsten Halogen Lamps | Quick Heat-up time, Good for shock heating, Used with short-wave reflector |

| Quartz Infrared Emitters | Energy efficient, Long-lasting life span |

| Ceramic Infrared Emitters | Wide range of wavelengths available, Available in low and high watt densities |

These lamps can help reduce cost cutting as well as being an innovative development in the industry. It is important to note that aluminum pans can usually be used in ovens; however, it is not recommended to put tefal pans or cold glass directly into the oven, as they may crack.

When cleaning the oven with easy-off or other cleaning products, it’s best to avoid using stovetop burners during this process due to possible fumes. While using the oven for cooking purposes, different temperatures will produce varying results – medium heat is typically set around 350°F. After turning off an oven, it can stay warm for a while depending on the model and how long it was on.

Some dishwashers have symbols indicated whether items are dishwasher safe or not but caution should always be taken when washing kitchenware.

Targeted and indirect method of drying

One efficient and innovative way to cure a powder coat without an oven is through targeted and indirect methods of drying. This method involves applying heat only to specific areas for faster and controllable curing.

Below is a table that compares the use of infrared curing systems versus conventional ovens in curing powder coats:

| Factors | Infrared Curing Systems | Conventional Ovens |

|---|---|---|

| Energy Efficiency | Uses less energy due to targeted application | Can be less efficient due to full oven usage |

| Curing Time | Can cure faster due to precise application of heat | Takes longer time compared to IR systems as the entire oven needs pre-heating and cooling down time before loading new batches. |

| Flexibility in Application Method | Easier to install, control, move, remove & setup -suitable for any shape or size (small or large) part provided the IR lamp can reach it. | Moving parts in & out may cause damage/wear on conveyor belt and other ancillary equipments which can be difficult maintenance-wise overtime |

It is essential to note that there are various approaches to curing powder coats without an oven besides indirect methods.

While this method has its unique benefits, care should be taken not to apply too much heat as it may negatively impact the finished product quality.

It is true that you cannot put cold glass in the oven as it can shatter due to thermal shock.

Why Choose Infrared Curing System Over Traditional Oven?

Infrared curing systems are preferred over traditional ovens due to energy efficiency and innovation. The process creates heat faster and ensures uniform curing, which results in a better finish. Infrared curing systems also do not require preheating and have a shorter curing time, which results in higher productivity. Additionally, they are safer to use and emit no harmful pollutants, making them more environmentally friendly. A pro tip for curing powder coat without an oven is to use a portable infrared lamp for spot curing.

Benefits for limited space situations and production speed

Infrared curing systems are a better alternative to traditional ovens due to their numerous benefits for limited space situations and production speed. Businesses that prioritize efficient energy usage and quick turnaround times can benefit greatly from this technology.

- Infrared curing systems require less floor space than traditional ovens, freeing up valuable working areas in small shops or factories.

- The technology heats up faster than a conventional oven, reducing the time it takes to manufacture products and increasing productivity.

- Infrared curing eliminates the need for lengthy cool-down periods or special ventilation systems, allowing businesses to coat more products per hour than they would with a traditional oven.

- This system requires no preheating time before starting a curing cycle, thus saving power and reducing costs during low-volume production runs.

One unique detail about infrared curing systems is that they work especially well with aluminum substrates, making them ideal for use in the automotive industry. Manufacturers can use these systems to cure powder coating on aluminum parts quickly and efficiently.

It is a fact that many sources suggest avoiding using bleach to clean ovens as it can be corrosive and damaging to the interior of the appliance.

Faster and more even powder coat job

Powder coating can now be done more efficiently and evenly without using an oven. This method is quick, safe, and effective in achieving high-quality results for your equipment.

Here’s a three-step guide to achieving a faster and more even powder coat job:

- Choose the right infrared curing system that fits within your budget as this will significantly reduce cure time compared to using convectional heating methods.

- Ensure that the surface to be coated is properly cleaned, pre-heated, and free of any contaminants such as oils or grease before applying the powder coat material.

- After applying the powder-coat material, let it sit for some accepted duration based on the product specification sheet to ensure best results.

It is worth noting that different materials take varying times to preheat or cool.

Regarding unique details, it is important to note that this process is only suitable for objects that are not affected by direct heat. Therefore materials such as plastic should not be used as they might melt instead of curing.

Last but not least, one real-life example of faster and more even powder coat job was when a production facility switched from convectional heating methods to an infrared system which lowered their curing times by 50% while still producing high-quality finishes at a fraction of the original cost.

Lower operation

One way to lower operation costs of powder coating without an oven is to consider using infrared curing systems. These systems can cure coatings at a faster rate, reducing the overall time and energy required for the process. Additionally, they can be adjusted to meet specific coating requirements, ensuring a consistent finish. Using these alternative methods can also eliminate the need for expensive heating equipment like ovens or burners.

It is important to note that when using infrared curing systems, it is advisable to use appropriately coated substrates that can withstand high temperatures. For instance, aluminum pans are safe for baking in an oven, but not all can withstand being used under an infrared system. In addition to substrate considerations, it is also recommended that you follow the manufacturer’s guidelines for optimal results and avoid potential damages.

Using alternative curing methods can be effective in reducing operational expenses while maintaining quality finishes for your products. By exploring different options like infrared curing systems and understanding their limitations and benefits fully, manufacturers can tailor their approach to create efficiencies that align with their specific business needs.

Pros and Cons of Infrared Curing System

Infrared Curing System – Advantages and Disadvantages

Infrared curing systems are a popular choice for powder coating without an oven. This method uses infrared lamps to generate heat and cure the powder coating. Here are some advantages and disadvantages to consider:

Advantages:

- Shorter curing time

- Reduced energy consumption

- Better temperature control

- Uniform heating

- Lower capital costs

Disadvantages:

- Higher equipment costs

- Limited cure depth

- Higher maintenance requirements

- Less effective on complex shapes

- Greater risk of damage to substrate

While infrared curing systems have several benefits, it is important to note that they may not be suitable for all applications. Additionally, the complex shapes of some substrates may make them less effective in achieving the desired cure depth.

A friend of mine recently had his car rims powder coated using an infrared curing system. Although the powder was cured perfectly, it was discovered that the heat had caused the tires to expand and the rims no longer fit. This serves as a cautionary tale to always consider the risks and limitations of any curing method before proceeding.

Pros

Infrared curing systems have become popular among industries for the efficient and effective curing of powder coats. They offer several advantages compared to conventional ovens, reducing operational costs and increasing productivity.

- Quick Curing: Infrared curing systems can cure powder coats almost instantly with high efficiency. This reduces production time and increases throughput, optimizing production processes.

- Environmental Friendly: It is an eco-friendly alternative that doesn’t require fuel combustion, making it a sustainable choice for businesses looking to reduce carbon footprint and environmental impact.

- Low Maintenance: As there are no moving parts involved in the process, these systems require very little maintenance. This makes them easy to service, with minimal downtime expenses when repairs or maintenance is necessary.

In addition to these benefits, infrared curing systems are also energy-efficient and allow more precise temperature control during the curing process- without compromising on quality.

Businesses looking to increase their production output while minimizing operational costs could benefit from investing in infrared curing technology. With its quick curing times, environmentally sustainable properties and low maintenance requirements– you don’t want to miss out on this opportunity for growth.

So if you’re in the market for a new oven or considering upgrading your current setup- consider the advantages of infrared technology and invest in a cost-effective solution today!

Saved floor space

Through the use of Pfaltzgraff stoneware dishes, homeowners and homemakers alike can save significant countertop and cabinet space. These durable and efficient dishes provide an excellent alternative to bulky kitchenware, allowing for a more streamlined and organized kitchen.

With their stackable design, Pfaltzgraff stoneware dishes also facilitate easy storage in cabinets or drawers. Their sleek and stylish appearance makes them a great addition to any kitchen, while their durability ensures they can withstand even the most challenging daily use.

When it comes to maintaining these dishes, homeowners simply need to wash them by hand or place them in the dishwasher for added convenience. Additionally, they are microwave safe and oven safe up to 350°F, making meal prep a breeze.

For ultimate peace of mind, consumers should always consult the manufacturer’s instructions before using any cookware or bakeware in infrared curing systems or convection ovens. As a pro tip, always be careful not to drop or bump Pfaltzgraff stoneware dishes as they may chip or break upon impact.

I may not know much about stoneware dishes, but I do know that the Circuit Breaker tripping is a sign to order take out.

Zoned and targeted heating

Heating Techniques for Pfaltzgraff Stoneware Dishes

Heating a specific area of Pfaltzgraff stoneware dishes, rather than subjecting the entire vessel to high temperature can cause thermal shock.Zoned and targeted heating techniques that employ infrared curing systems or preheated pans should be used instead.

Zoned and targeted heating refers to the process of applying heat to specific areas of an object while leaving other areas unaffected. This technique is useful when heating Pfaltzgraff stoneware dishes, as subjecting the entire dish to high temperatures can cause it to crack due to thermal shock. Infrared curing systems or preheated pans are often used for this purpose, as they allow for controlled heating of specific areas.

It is important to note that using zoned and targeted heating techniques requires careful monitoring and control, as uneven heating can still lead to thermal shock. Additionally, it is always best to refer to the manufacturer’s instructions for proper use and care of these dishes.

To avoid risking damage to your Pfaltzgraff stoneware dishes, it is crucial to use appropriate heating techniques such as zoned and targeted heating with caution. Stay clear of high-temperature cooking methods that may result in cracks and further damage to your dishes.

Quick to heat up and cool down

When it comes to heating and cooling down, there are some important things to consider. Appliances like infrared curing systems may heat up quickly, but that doesn’t mean they cool down quickly too. It’s important to understand the unique features of each appliance before attempting to care for them on your own.

Using proper care instructions can save you money in the long run, but it’s best not to take on these tasks alone. Many people wonder whether they can put an aluminum pan or Tefal pans in the oven. Others may ask about baking in oui jars or using a gas oven with quick preheat times.

It’s essential to avoid using harsh chemicals when cleaning your oven. Even if there is white residue remaining after cleaning, it’s important to use appropriate products instead of abrasive cleaners like Comet. It’s also vital to avoid putting cold glass in the oven as this could cause cracking or breakage.

If you’re unsure about how to operate special features of your kitchen appliances or have discovered an electrical burning smell coming from your oven, reaching out for professional help can prevent potential danger and damage to your home.

Don’t let FOMO (Fear Of Missing Out) guide your decision-making process and potentially cause expensive mistakes. Always seek reliable resources and professionals when it comes to caring for your appliances.

Why use a boring old oven when you can zap your coatings to perfection with infrared technology?

Highly efficient energy and heat distribution

The cooling fan in an oven is crucial to ensure highly efficient energy and heat distribution. It is responsible for preventing the oven from overheating, promoting even cooking and reducing energy consumption. Without this, heat can build up inside the appliance and cause damage, or uneven heating of food can occur.

Ovens with infrared curing systems may need a stronger cooling fan to maintain a safe temperature. The fan draws cool air into the oven through vents to cool hot components like heating elements.

In addition to promoting even cooking, a cooling fan prevents hotspots that can damage bakeware like aluminum pans or Tefal pans that are not safe for use with high temperatures. Glass bakeware like Oui jars should always be used at room temperature before baking in the oven.

It is essential to preheat gas ovens for optimal performance and avoid white residue after cleaning. To calibrate such ovens for accurate temperature control, set them to the lowest oven temperature, wait 10 minutes, then add 20 degrees Celsius until you find your desired level.

Why settle for a lukewarm baking experience when you can have a sizzling affair with Pfaltzgraff’s oven cooling fan?

Easy to use and control

Pfaltzgraff bakeware offers effortless baking with precise temperature control. Its user-friendly and intuitive design makes it easy to use without the need for extensive experience or technical knowledge. Whether you are a novice or a seasoned baker, this bakeware will fulfill your expectations by providing consistent results every time.

Moreover, Pfaltzgraff bakeware is versatile and perfect for baking anything from savory dishes to sweet treats with evenly distributed heat. Its excellent infrared curing systems provide better browning and crisping of food items in less time than traditional ovens.

If you want to enjoy delicious baked dishes without any hassle, invest in Pfaltzgraff bakeware today. Don’t miss out on the opportunity to elevate your baking game with effortless ease!

From bakeware to infrared curing systems: because who doesn’t love a good temperature limitation?

Can increase speed

Alternative cooking methods can expedite the cooking process. By utilizing infrared curing systems or speed bake ovens, food can cook faster and efficiently. Additionally, adjusting oven temperature settings to accommodate diverse dishes can reduce the preheat time for your gas oven.

When baking, replace typical baking vessels with alternatives such as aluminum pans, teflon-coated cookware, or glass jars that are heat-resistant and safe for use in the oven. When checking if your items are suitable to use in an oven, ensure they are labelled as being safe to use in higher temperatures. It is best to avoid using cold dishes when placing them in a hot oven to prevent them from shattering due to thermal shock.

Another useful tip is to clean your appliance regularly so that it maintains its original state and keeps its integrity over time. To clean your oven without excessive cleaning product residue build-up or white residual patches after cleaning, utilize brands that specialize in cleaning ovens and follow instructions carefully.

To decrease overall cooking time, occasionally turn on the broiler feature of your oven instead of just relying on the bake setting. When using other appliances simultaneously as well as saving power consumption during usage times with low power consumption options like microwave ovens or toaster ovens can be effective too.

By following these tips along with other helpful suggestions specific to you may result in improved cooking speed while maintaining consistent high-quality meals cooked properly every time you turn on your kitchen appliances. Get ready to be enlightened about Infrared Curing Systems, because conventional ovens are so last season.

Suitable for solvent-based coatings

This product is compatible with coatings that are solvent-based. These types of coatings involve a chemical dissolved in a solvent which can dissolve other substances to create the desired consistency. To ensure best results, it is important to follow use and care instructions closely, keeping in mind any equipment, environmental or application requirements.

| Suitable for solvent-based coatings |

|---|

| Compatible with chemical dissolved solvent |

| Follow proper use and care instructions |

It is important to note that this product must be used with infrared curing systems. Additionally please do not put aluminum pans or glassware straight out of the fridge into the oven as it may cause cracking. Never clean with bleach and instead use approved cleaning products for the task at hand.

When using solvent-based coatings such as enamels or metal paints, extra ventilation will be needed due to fumes given off during application and drying processes.

The historic evolution of creating a suitable alternative for solvent-based coating stems from both health and environmental concerns. Over time it was discovered that some solvents could create harmful air pollution and could have toxic properties when absorbed through the skin or inhaled. Further research led to exploration of less hazardous options such as combining natural oils such as flaxseed oil or linseed oil with resins or natural dyes which could then be applied safely.

From saving space to zoned heating, an infrared curing system is like a superhero for powder coat jobs.

Cons

When it comes to curing powder coat without an oven, there are several cons to consider. These include:

- Limited Size Capacity: Most infrared curing systems available for home use have a smaller capacity than traditional ovens. This means that larger items may not fit or may require multiple curing sessions.

- Longer Cure Times: Curing powder coat without an oven can also take longer than using a traditional oven. The length of time will vary depending on the specific equipment used.

- Higher Energy Costs: The cost of running infrared curing systems can be higher due to their increased energy consumption compared to traditional ovens.

While these cons may seem daunting, there are still benefits to using alternatives like infrared curing systems. They offer flexibility and portability, allowing for powder coating projects in areas without access to a traditional oven.

Recently, a friend shared their experience with successfully curing powder coat on small items at home using a propane torch and heat gun combination method. While this approach requires caution and attention to detail, it highlights the creativity and resourcefulness of those looking for alternative ways to cure their powder coatings.

Temperature-sensitive substrates can be challenging

Working with delicate materials that are sensitive to changes in temperature can often pose significant challenges. Whether dealing with infrared curing systems or determining if a particular pan can go in the oven, it is important to be aware of the potential risks to prevent damage to your substrate. With factors such as the duration and intensity of exposure, it’s crucial to have proper knowledge and control over the conditions.

Understanding the complexities associated with temperature-sensitive substrates can help you make informed decisions in terms of choosing the right equipment and procedures for production. Elements such as optimal temperature ranges, rate of heating/cooling, and consistent monitoring techniques should all be taken into account when working with these types of materials.

Additionally, other considerations such as cleaning methods and being aware of common issues like white residues left behind after cleaning, can also ensure that your substrate remains in top condition. By taking a proactive approach and staying informed about these various aspects, you can minimize any potential downtime or costs associated with product defects.

Pro Tip: When working with temperature-sensitive substrates, always take a cautious approach to ensure proper handling and minimize any risks associated with exposure to heat or other environmental factors.

Not always straightforward to scale up

Scaling up text-to-speech generators is not always a smooth process. The complexity involved requires advanced technical skills, and models need fine-tuning to enhance voice quality and accuracy. Moreover, the cost of hardware upgrades for large-scale operation can be financially daunting. In addition, training data selection is critical, and ethical considerations such as bias detection must be taken into account. Overcoming these challenges requires collaboration between experts to ensure scalability without compromising on quality.

One unique consideration in scaling up involves the integration of complementary technologies like MuseNet’s musical generation models with more conventional TTS systems. Also, using infrared curing systems for voice coils can help scale up high-volume manufacturing while improving sound quality by eliminating air gaps.

A true fact about text-to-speech generators is that they are already used in multiple industries, including healthcare. For example, voice-enabled medical dictation software has been developed for radiologists to increase efficiency and accuracy when interpreting patient images.

Who needs a conventional oven when you can have targeted and efficient heating with an infrared curing system?

Harder to dry heavier coatings

Drying heavier coatings can be a more challenging task, especially when using traditional methods. These coatings take longer to dry compared to lighter ones, which results in extended production times and higher labor costs. But with the help of infrared curing systems, this issue can be resolved. These systems employ modern technology to reduce drying time significantly. As a result, businesses can save time and money while increasing their productivity levels.

In addition to utilizing infrared curing systems, there are other tips that businesses can follow for faster coating drying times. For instance, proper surface preparation before application is crucial. Also, it is recommended to keep the coated surfaces in a warm environment with good ventilation. Moreover, using higher-quality materials and applying thinner coats can speed up the drying process.

By implementing these precautions during coating applications, businesses will see significant improvements in their efficiency levels and reduced production costs. Creating an effective production plan is essential for any business aiming to maximize its profits.

It is vital for businesses not to ignore the importance of following instructions during coating applications as it can lead to safety hazards and increased costs associated with repairs or re-applications. By implementing all recommended guidelines and utilizing modern technology such as infrared curing systems, companies can reduce their risks while optimizing their production processes for best results. Don’t miss out on these industry-standard practices!

You won’t need a traditional oven after learning about the benefits of an infrared curing system, unless you enjoy wasting time and money.

Operating an Infrared Curing System

An In-Depth Look at the Functioning of Infrared Curing Systems

Infrared curing systems are a highly efficient method of curing powder coatings. The infrared process uses electromagnetic radiation that heats the part through the energy transfer, instead of relying on convection for heat transfer. This results in a uniform heat distribution and shorter curing periods, making the process much faster. Infrared curing systems come in several forms including electric, gas, and hybrid variants. The choice of which variant to use depends on the curing specifications required by the job.

To get optimal results from an infrared curing system, ensure that the system is properly installed and calibrated to meet the job specifications. Follow the manufacturer’s guidelines for the installation and calibrating processes. Additionally, operators should be trained to handle the equipment safely. They should understand how to adjust the settings to ensure proper curing.

Lastly, all maintenance schedules should be followed to avoid any malfunctioning or unexpected failures. Regular maintenance ensures that the system works at its peak performance, and as a result, offers a better return on investment.

Ready to experience the advantages of infrared curing systems? Get in touch with us to learn more about our infrared curing system products and services. Don’t miss out on the opportunity to improve your business operations.

Easy to operate

Operating an infrared curing system for powder coating is a straightforward process that requires minimal effort and knowledge.

To operate, follow these five simple steps:

- Ensure that the part’s visible portion is clean and free of debris.

- Place the part in front of the infrared heating source.

- Activate the heating source and adjust the height to ensure proper coverage.

- Maintain an appropriate distance between the heat source and the part and monitor progress throughout the curing process.

- Allow sufficient cooling time before handling or further processing once curing is complete.

It is essential to note that timing varies based on factors such as parts being cured, their size, environmental conditions, etc. Therefore adjustments may need to be made to ensure optimal results.

Another crucial aspect of operating an infrared curing system is safety. Ensure you have adequate protective gear like gloves, eyewear when using the device.

It’s interesting to know that unlike traditional ovens’ convection-based heating, Infrared Curing Systems utilizes infrared radiation to transfer heat directly onto parts coated with powder. This allows for rapid, precise heating with energy efficiency up by over 50%.

Positioning and moving the lights

Proper positioning and movement of infrared curing systems is vital for a successful powder coat cure. Achieving optimal heat distribution requires proper placement of the lamps over the target area, minimizing distance and angle variations.

Here’s a simple 5-Step Guide:

- Positioning the lamps uniformly around the part ensures even heating.

- Avoid placing the lamps too close to avoid hot spots or melting of the part’s surface.

- The lamp angle should be adjusted accordingly to ensure even heat coverage on all surfaces.

- Keep the lamp steady throughout the curing process by securing it firmly to prevent any movement.

- Avoid moving the lamps during curing since it could lead to uneven heating and damage to your powder coat.

It’s important to note that yellow or brown buildup on electrical connections can cause sparking and shortening lifespan of infrared cure bulbs.

Safety Tips for Infrared Curing System

Infrared curing systems are efficient and fast, but they also pose potential safety hazards. Follow these three simple steps for safe usage:

- Ensure that all flammable materials are stored away from the curing area.

- Wear protective gear, such as gloves and goggles, to prevent burns or eye damage.

- Allow the system to cool down sufficiently before handling or storing the equipment.

To avoid accidents, it’s important to never leave the system unattended and to follow manufacturer’s instructions carefully.

It’s important to note that each system may have unique safety requirements. Always read and follow the manufacturer’s instructions and seek professional guidance if necessary.

According to the U.S Consumer Product Safety Commission, silvery-white residue left in the oven after cleaning may indicate that the oven cleaner was not rinsed thoroughly or that the coating of the oven is damaged.

Source: https://www.cpsc.gov/s3fs-public/5025.pdf

Precautions to keep the work environment safe

When working with infrared curing systems for powder coating without an oven, it’s important to take precautions to ensure the safety of your work environment. Here are some tips to keep in mind:

- Wear protective gear such as gloves and goggles when handling materials and operating machinery.

- Ensure adequate ventilation in the workspace to prevent accumulation of hazardous fumes or dust.

- Use caution when using electrical equipment around liquids or moisture, as this can increase the risk of shock or electrocution.

Additionally, it’s important to be aware of other safety risks that may not be related directly to the use of infrared curing systems. For example, when cleaning an oven with chemicals like Easy-Off, make sure to turn off gas stoves entirely before doing so to avoid explosions caused by pilot lights still being on.

To minimize risks in the workplace, consider incorporating suggestions like double-checking all machinery before use, properly labeling hazardous materials and storage areas, and regularly inspecting electrical equipment for damage. By taking these simple steps towards a safer environment, you can better protect yourself and others while working with infrared curing systems for powder coating.

8 safety rules for operating an Infrared Curing System

Operating an Infrared Curing System requires following proper safety protocols to prevent accidents and injuries. Here are some guidelines that you must adhere to:

- Wear the appropriate safety gear such as gloves, goggles, and protective clothing.

- Ensure that the curing area is free of any flammable materials or substances that can cause a fire.

- Always maintain a safe distance between yourself and the system during operation.

- Avoid opening the Infrared Curing System while it is in use. Doing so can cause severe burns.

- The system should not be operated if there are loose wires, damaged cords or other electrical hazards present in the area.

- Do not touch any hot surfaces of the Infrared Curing System without using proper protective equipment.

- Turn off and unplug the system after use and let it cool before storing or transporting.

- Clean and maintain the Infrared Curing System regularly to ensure proper functioning.

It’s also vital to note that failure to adhere to these rules could result in injury, damage to property or even death.

When operating an Infrared Curing System, always prioritize safety first. Ensure that everyone involved follows all guidelines carefully for a successful completion of your project.

A true story highlights how neglecting safety could lead to disastrous consequences. A man who was curing his powder-coated metal with an oven got distracted by a phone call when he left his components unattended inside the oven. It soon caught fire due to excessive heat, causing significant harm to him and harm his property. This unfortunate incident illustrates how essential it is always not only important but also critical to follow best practices when working with infrared curing systems for your safety and those around you.

FAQ

In this article, we explore the alternative methods for curing powder coat without an oven. Here are some frequently asked questions about the topic:

- Can I cure powder coat without an oven?

- What are the alternative methods for curing powder coat without an oven?

- Are there any disadvantages of curing powder coat without an oven?

Alternative methods for curing powder coat without an oven include using infrared curing systems or heat lamps. Powder coat can also be cured with a heat gun or torch, but these methods are only suitable for small projects. While these methods can work, they may not produce the same quality finish as an oven cure.

It is important to note that curing powder coat without an oven may take longer and require more effort. It may also emit fumes, so ventilation is necessary. Additionally, while powder coating is a durable and long-lasting finish, curing powder coat without an oven may compromise its durability.

Some unique details to consider when curing powder coat without an oven include the type of powder coat being used and the size of the project. It is important to follow the manufacturer’s instructions and test the curing process before proceeding with the project.

In a true story, a small business owner who lacked an oven for powder coating resorted to using a heat gun. While the finished product looked satisfactory, it was not as durable as an oven-cured finish and the process was time-consuming. Eventually, the owner invested in an oven for better quality results.

Frequently asked questions

If you are searching for ways to cure powder coat without an oven, here are some frequently asked questions that you should know.

- Can I use infrared curing systems as an alternative?

- Can I put aluminum pans or metal in the oven?

- Can Tefal pans go in the oven?

- What about baking in oui jars?

- How long does a gas oven take to preheat, and how do I reset its button?

- Is it safe to put cold glass in my oven?

Apart from the above questions, there may be other unique details that interest you. For example, if your oven has white residue after cleaning, try wiping it down with vinegar and baking soda.

Pro Tip: To ensure a proper cure when using an alternative method like a heat gun or torch, always double-check by conducting adhesion and corrosion tests.

Does Infrared work better in vacuum situations with little to no air?

Infrared curing systems are efficient in high temperatures and vacuum situations with minimal air. The absence of air allows for quicker and more precise heat transfer, especially when used with materials that have low absorption rates.

Furthermore, the infrared system’s precise heating allows for curing powder coatings without using an oven, making it ideal for tight spaces.

One unique feature of the infrared system is its ability to set accurate temperature controls. With its advanced sensors and wavelength selection capabilities, it can precisely direct heat to specific areas on a target material.

The use of infrared technology goes back decades. NASA pioneered its use in space missions as an optimal solution to overcome the lack of oxygen and cold environment in space. Since then, many industries have adopted the technology for various purposes.

Can I combine Infrared and conventional ovens?

Combining Infrared and conventional ovens is not recommended as it may compromise the curing process. The two ovens have different heating mechanisms, which result in a non-uniform temperature distribution and inconsistent curing of the coating. Curing problems such as insufficient adhesion, low gloss, and color variation may arise from using both ovens simultaneously or sequentially.

Infrared curing sytems are efficient alternatives that cure the powder coat quickly while using less energy. These systems emit IR radiation that penetrates the powder coat layer and cures it from within, resulting in better quality finishes with superior adhesion and corrosion resistance.

It is important to note that each oven has specific guidelines that should be followed when operating them. Failure to adhere to these guidelines could lead to malfunctioning or damage of equipment. For instance, putting an aluminum pan in the oven could lead to warping or uneven heating due to thermal conductivity differences between aluminum and other materials.

A true story is told of a baker who put cold glass in a preheated oven without considering thermal shock. The glass shattered into small pieces causing significant damage to the oven and ruining the baked goods. Therefore, always double-check what you can place in your oven before loading it up.

Is Infrared safe to work with?

The use of infrared in curing powder coat raises safety concerns. Though generally safe, proper usage is advised to avoid injury. The type of infrared used, exposure time and maintenance practices determine the level of safety.

The infrared radiation emitted from lamps or heaters should be handled with utmost care. Protecting skin and eye exposure is paramount when handling any form of infrared radiation.

In addition to personal safety measures, strict adherence to manufacturer’s recommended usage limits and maintenance routine is important for longevity of equipment. Infrared ovens should be well-maintained to avoid heat accumulation, which may cause a fire outbreak over time if not checked regularly.

When setting up an oven or purchasing one for your powder coating needs, it is vital to consider various factors besides safety when choosing a type that best suits your needs and environment.

Several accidents have been reported due to negligence in handling this equipment. Proper training on how best to handle it will indeed go a long way in preventing injuries that lead to fatalities.

Is Infrared environmentally friendly?

Infrared technology is an eco-friendly alternative to traditional heating methods. The process involves heating objects rather than the surrounding air, reducing energy consumption and carbon emissions. This method also reduces waste since it requires no preheating, unlike conventional ovens.

Using infrared technology in cooking appliances provides faster and more efficient heating while consuming less power, leading to lower utility bills. This technology also increases the life expectancy of cooking equipment by reducing wear and tear on mechanical components compared to traditional ovens.

Moreover, infrared ovens emit less volatile organic compounds (VOCs) and have no open flames, which makes them safer for human health and the environment. Unlike electric or gas-fired systems, infrared ovens do not generate harmful pollutants that can negatively impact indoor air quality.

If you are thinking of purchasing an infrared oven, you may want to consider getting a model with temperature control features such as digital temperature control. With this feature, you will be able to set an accurate temperature range for your cooking needs while avoiding overheating or burning food.

To further reduce energy consumption and save money on utility bills when using an infrared oven, consider using a baking stone for even heat distribution or using glass or ceramic containers instead of metal ones since they heat up faster.

Overall, infrared technology offers numerous benefits for both the environment and personal use in terms of energy efficiency and safety. As our concerns about climate change continue to grow, adopting eco-friendly technologies like infrared heating can help reduce carbon footprints while still meeting our everyday needs.

Which one is more expensive

When it comes to cost comparison, which option is pricier? Let’s take a closer look at the numbers.

| Appliance | Price Range |

|---|---|

| Conventional Oven | $200 – $2,000 |

| Toaster Oven | $30 – $300 |

While conventional ovens are more expensive initially, they have longer lifespans and can cook larger quantities of food. Toaster ovens are a budget-friendly alternative for smaller meals and quicker cooking times. When considering which appliance to purchase, also take into account the intended use and frequency of use. It may be more cost-effective to invest in a higher-priced oven with greater durability if it will be used frequently. Don’t miss out on making the right decision for your needs and budget. Do your research thoroughly before purchasing any appliance.

Which one costs more to operate on a regular basis?

When it comes to the cost of operation, people often wonder which option is more expensive. To clear your confusion, we have compared the average costs of using an oven and a stove top in terms of electricity or gas consumption.

Here is a comparison table of ‘Electricity/Gas Consumption Comparison: Oven vs Stove Top’ based on average usage:

| Appliance | Average Watts | Hours Used Per Week | Energy Cost Per Year |

|---|---|---|---|

| Oven | 2400 | 10 | $163 |

| Stove Top | 1200 | 14 | $138 |

As you can see, an oven consumes almost double the wattage when compared to a stove top which makes it slightly more expensive to operate but both are not drastically different in cost.

If you prefer convenience over cost, then purchasing a new oven with advanced features like convection or self-cleaning modes might be worthwhile for you.

It’s important to keep in mind that these estimates are based on average usage and energy prices vary depending on where you live and time of day. Consult your electricity/gas supplier for personalized insights.

According to Consumer Reports, experts advise caution when putting wine bottles into the oven as they pose a danger of explosion due to uneven heating.

Do I need special coatings to use Infrared?

Using Infrared heating technology does not require any special coatings. Infrared can heat almost all materials, including metals, ceramics, plastics and wood. The powerful rays penetrate into the surface of the material for even heat distribution, unlike traditional ovens.

Infrared is compatible with a wide range of coating types. Due to the quick curing time and energy efficiency of infrared systems, many types of coatings work well with this technology. It’s important to note that some specific coatings may require adjustments in temperature or timing to achieve optimal results.

It is crucial to select a coating that can withstand high temperatures without damaging or producing fumes during the curing process. Before applying any coating using Infrared technology, it is essential to check its compatibility with this heating method.

Interestingly, an automotive customer turned to Infrared for powder coat curing when one day before a show they discovered that their oven was broken. A local representative was able to loan them some equipment so they could start processing immediately. Even though they had previously thought about using infrared for planned expansion, this accident became the push they needed to take action.

Conclusion

The Solution to Powder Coat Curing Without an Oven

If you are looking for an alternative to oven curing for powder coat, you have come to the right place. This article provides you with effective methods to cure powder coat on your own without using an oven.

In this article, we have covered different ways to cure powder coat without an oven such as using an infrared lamp or a heat gun. These methods can help you achieve a perfect and durable finish for your powder coat project.

It is important to note that every method has its limitations and drawbacks, so you should choose the method that works best for your specific requirements. Also, make sure to take adequate safety precautions when working with equipment that emits heat.

If you want to avoid missing out on a cost-effective solution to curing powder coat without an oven, try out the methods described in this article and achieve excellent results.

So go ahead and give these techniques a try today.

Final Thoughts

In wrapping up this discussion, it is important to emphasize that curing powder coat without an oven is a viable alternative. By following the proper steps and using the right equipment, such as an infrared lamp, you can achieve professional-looking results without the added expense of an industrial oven. What’s more, this method offers greater flexibility in terms of the size and shape of the parts you can cure.

For a flawless finish, take the time to properly prepare your surface and select a high-quality powder coating formula. With these considerations in mind, you’ll be on your way to achieving long-lasting, attractive coatings on your project pieces. Don’t miss out on this opportunity to elevate your DIY game and save money in the process.

Five Facts About How To Cure Powder Coat Without Oven:

- ✅ Using a heat gun can cure powder coat without using an oven. (Source: Powder Coating: The Complete Guide)

- ✅ Powder coat can also be cured using infrared lamps or ceramic heaters. (Source: Pro Powder Guide)

- ✅ Proper curing time and temperature are crucial for a durable powder coat finish. (Source: Eastwood Guide to Powder Coating)

- ✅ The thickness of the powder coat can affect the curing process. (Source: Powder Coating Institute)

- ✅ Preheating the item before applying the powder coat can help improve adhesion and curing. (Source: Powder Coating Institute)

FAQs about How To Cure Powder Coat Without Oven

Can you cure powder coat without an oven?

Yes, you can cure powder coat without an oven. Some options include using a heat gun, propane torch, or infrared lamp. However, these methods may not provide the same level of consistency and durability as oven curing.

Is it safe to put an aluminum pan in the oven?

Yes, it is safe to put an aluminum pan in the oven. Aluminum is a good conductor of heat and can withstand high temperatures without warping or melting.

Can you bake in Oui jars?

No, it is not recommended to bake in Oui jars. The glass used for these jars is not designed to withstand high temperatures and can shatter or break in the oven.

How do I reset the Frigidaire oven?

To reset a Frigidaire oven, locate the reset button on the control panel and press and hold it for 3 seconds. This will reset the oven’s settings to their default values.

How do I light the pilot light in my Hotpoint oven?

To light the pilot light in a Hotpoint oven, turn the gas valve to “pilot”. Use a match or lighter to ignite the pilot light and hold down the pilot button for 30 seconds to ensure it stays lit.

Can I use stove top while cleaning oven with easy-off?

No, it is not recommended to use the stove top while cleaning the oven with Easy-Off. This can create a hazardous environment and may damage the stove top. It is best to clean the oven when the stove is not in use.